Circular Economy: Beginning with the End in Mind

Plastic is not the villain...it’s how we use it and treat it. The issue is in the design of packaging, manufacturing plastic single use and throw away. Instead, we need to be thoughtful of the end-life. We need to design plastic products so they can be easily re-used, recycled or re-purposed. Further, we need to establish and educate and track various types of plastic to allow for consumers to make better decisions on a packages next life. Right now confusion reigns and plastic products have almost no place to go but the landfill as less than 9% are recycled.

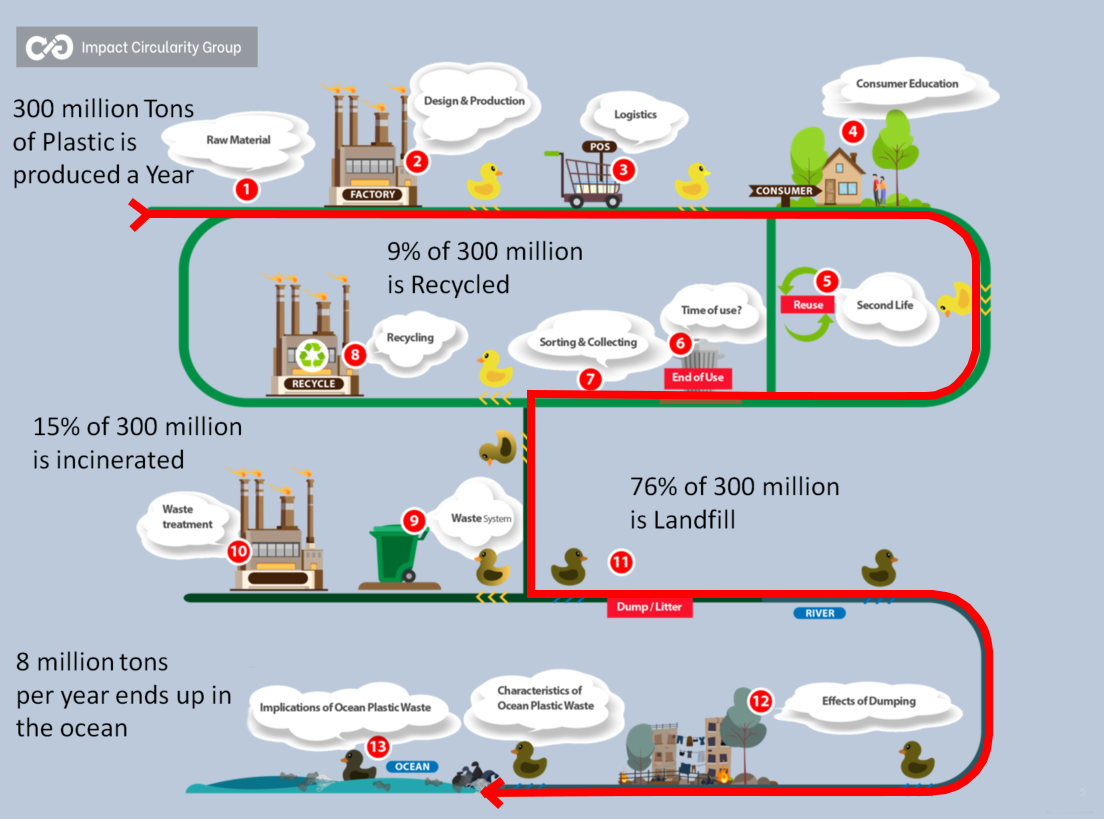

In a recent article, titled, “The Facts About Plastics,” we introduced the concept of the circular economy. Illustrated again here below, the circular economy shows the path of a “rubber ducky” (representing a plastic package) as it makes its journey from raw material through to its end life. Several potential end life scenarios exist here, some far better for the environment and our economy.

At present, the flow of the “circular economy” is quite non-circular indeed...and rather follows the path of the highlighted red line. Most plastic-based products end up in a landfill, the ocean or being incinerated, all of which have negative, environmental consequences. Image Courtesy: Impact Circularity Group

As you can see from the graphic above, the “rubber ducky” can go one of two ways. The duck can stay in the light green circle, feeding a truly circular economy, and greatly-reducing negative environmental impact, or it can fall off after stage 7 and head to a landfill, incinerator or directly into our waterways. As pointed out in our first article, The Facts About Plastics, our goal is to design products that still optimally protect the packaged-product, but also help to give the package another useful life after the completion of its initial, intended use. Such design considerations will allow the rubber ducky to stay in the light green loop...reducing negative environmental impact and providing feedstock for new, valuable materials.

Changes to Design and Production

Process 1 starts with beginning to identify feedstock of post-consumer resources that have already been recycled. Currently we, the manufacturers, need to build those feedstocks by providing enough pure, raw material that can be identified properly and sorted economically to ensure a reliable material supply chain.

The future involves a package that actually can be recycled, focusing in on materials that have enough demand to create a reliable marketplace for processors, collectors and manufacturers. We need to have a universal way of identifying what those materials are to facilitate effective, economical sorting by the consumer and eventually by recyclers. Once you have clean, second-life material, and enough of it, you begin to create an end market that will demand that material and use it for feedstock. This demand can be increased by consumer sentiment and legislative action.

The logistical pathway of a plastic bottle is shown here. Key to this cycle making sense is the distance from collection to sorting, its efficiency, and then the distance to then deliver the feedstock to a manufacturing facility. Image Courtesy: epa.gov

Local Logistics

While changes to design and production can firmly move the needle of the circular economy, the logistical aspect and the importance of how localized recycling plants are to the source of feedstock is also critical. The need to create the local infrastructure to handle the inflow and processing of recyclable material needs to make sense from a pickup and travel standpoint. In other words, if the recycling plant is 300 miles away, the fossil fuel used to get the feedstock from A to B would outweigh the recycling benefit. To improve the logistical efficiency of the transportation of recycled goods and the distribution of recycled resin back into the circular economy, governments will most likely need to step in with initial subsidies. This will likely be needed until better collection and sorting of recycled goods and manufacturing goods of recyclable material can be achieved. Once more efficient facilities are in place, this will allow recycled content to fulfill the raw material feedstock of a circular economy and generate enough critical mass to make those goods valuable to the free market.

Consumer Education

Education of consumers, which actively buy products with recycled or renewable content, is integral into fueling the circular economy. Preferably you need build in an insurance policy to ensure that if packaging does make it into the natural environment, waterways or terrestrial, that it will degrade in a way that will significantly reduce the impact on flora and fauna as compared to current plastics that fail in this mission. However, the focus should be prioritizing the recycling and re-use of the plastics used in packaging.

Summary

As we analyze and dissect the pathway of the circular economy, we are taking things “bit by bit.” Look for blog post #3 soon, which will take up the next steps of the journey of the rubber ducky and how things can and need to change to get us closer to a world that has less waste and provides more opportunities. A world that looks at all of the resources we use and extract as important and valuable.